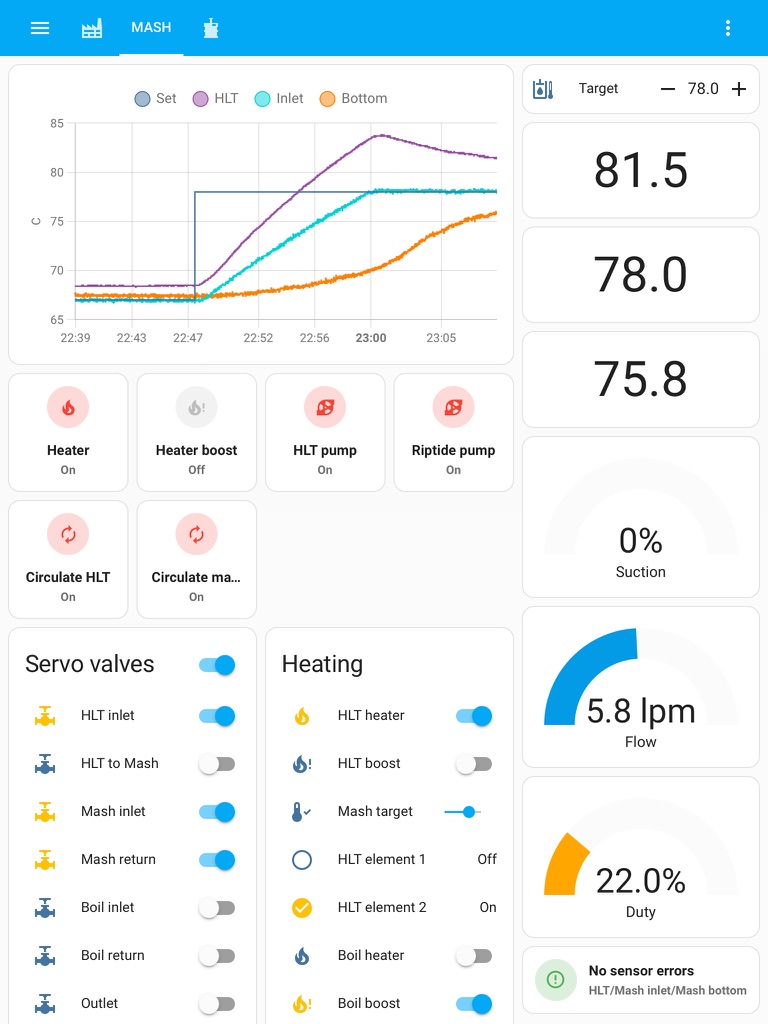

Many brewers use manometers or clear hoses at the bottom of the MLT to monitor the pressure below the grain bed. We have taken it to the next level and put a differential pressure sensor (1 psi range) between the bottom and top of the MLT to be able to digitally monitor and log the relative pressure below the grains. This is useful for controlling flow through the bed so that one do not put too much “suction” on the bed that might make it stuck.

The scale range from 0 % to 100 % “suction” where 0 % is calibrated at no flow, i.e., the pressure at the bottom is the highest and depends only on the weight of the water in MLT. At 100 % there is no force from the liquid in MLT and the pump is actually dragging the wort through the bed. That would correspond to the liquid level, in a tube alongside the MLT connected to the bottom, being more or less at the bottom of the MLT. We are normally aiming for no more than 60 % “suction”.

The digital manometer is displayed at the GUI.

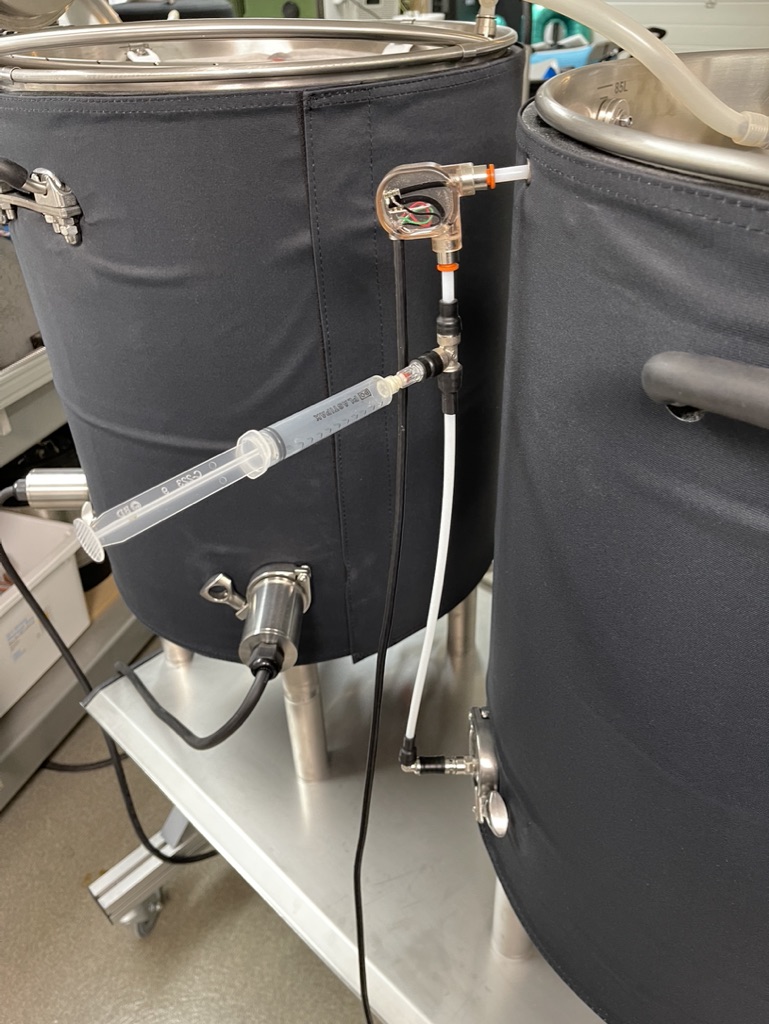

The tee and syringe is used for forcing air into the tubing and pushing any liquid out at the bottom of it. The tubes are very thin and any liquid inside the tubing would give a false result. There is a non-return valve at the inlet of the tee where the syringe is connected.

The sensor housing is made the same way as the sensor for the venturi pipe flow meter.