(click for more info.)

(click for more info.)

(click for more info.)

(click for more info.)

Blog posts

Use links above (click the images) for main articles.

-

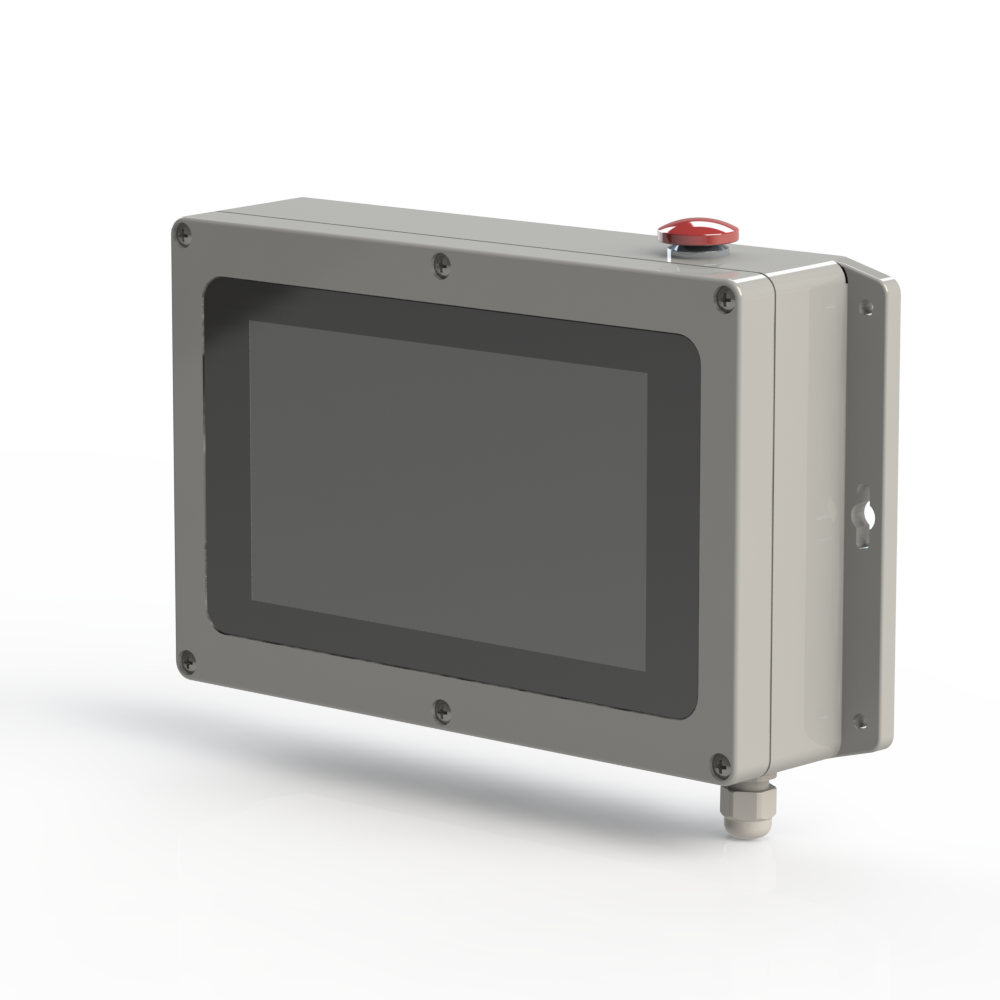

The LoniBrew controller is here!

Read all about it at the systems main page!

-

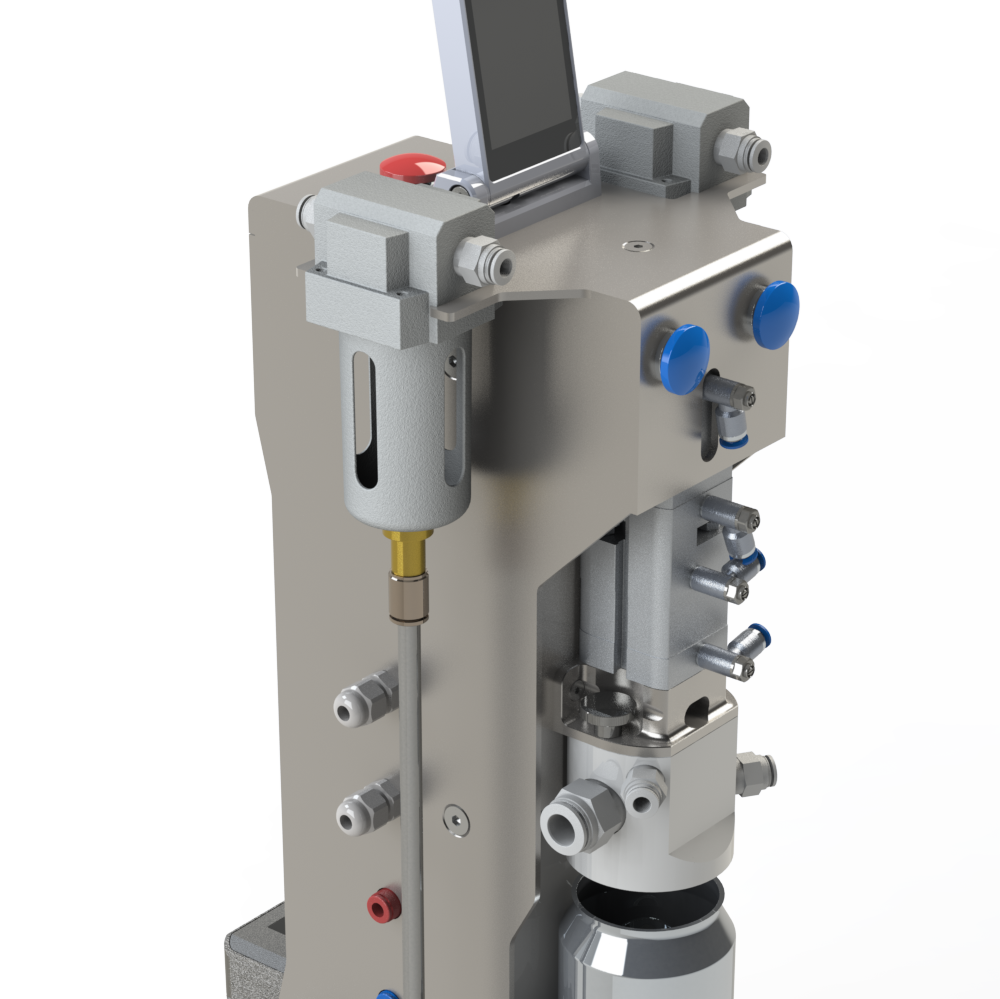

The LoDoFiller is here!

Something we have been working on for a long time! Check out the main page for the system!

-

Sanitary pinch valves, updated design

Discover Our Redesigned Pinch Valves We’ve upgraded our original pneumatic pinch valves with a durable anodized aluminum body, offering enhanced…

-

View our brewery in 3D

Not complete but you get the picture

-

Gammabrewery Showcases Innovative Brewing Solutions at Beer and Taste 2024

We’re excited to announce that Gammabrewery, in collaboration with Winterland Brewery and Lonitech AB, will be presenting our latest brewing…

-

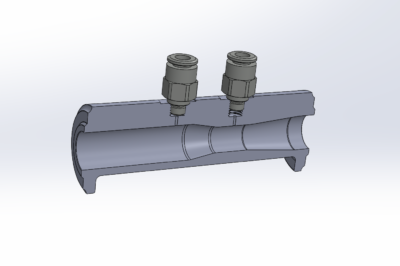

Venturi pipe for flow measurements

As we were going through the brewery’s hose system and replacing the sanitary valves, we also found the need to…

-

Pneumatic pinch valves

Due to our constant pursuit of enhancing our system, we began reevaluating hoses and flows within the brewing system. The…

-

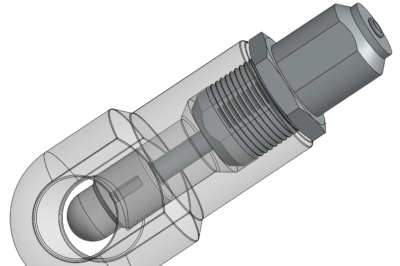

Cleaning adapter for the sample coil

We think that flushing the Brewtools sample coil after taking a sample is kind of messy and designed and printed…

-

Volume sensor for the fermenter (from xxx)

Pending an NDA (non disclosure aggrement) with yyy.. can’t say more right now 😉

-

Grain conditioning experiments

At the beginning of our career as brewers (about 2 years ago) we experimented with conditioned grains to boost the…

-

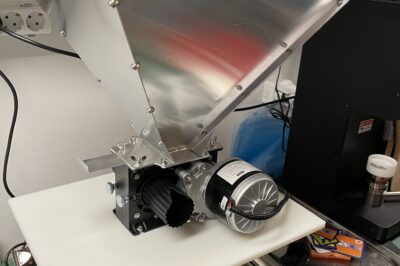

The NEW mill

Fell for the add on Facebook and ordered the KegLand MaltZilla Premium. Citing KegLand The MaltZilla Diamond Mill is quite…

-

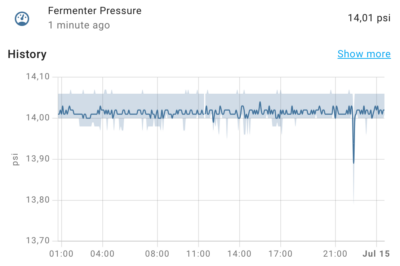

Electronic spunding valve

We have thought about building an electronic spunding valve for a while. We have measured pressure accurately and logged it…

-

Volume sensor for the fermenter (from weight)

The differential pressure based volume sensor is kind of tricky to use and have a lot of “moving parts” so…

-

Volume sensor for the fermenter (from differential pressure)

Knowing the “exact” wort volume in a fermenter is “crucial” for quality control during the brewing process. However, measuring the…

-

Inline Filter Kit

We just had to have one 🙂

-

CIP-lid for the brewery

We use a CIP-ball for the fermenter and it works really great. We would like to use CIP on our…

-

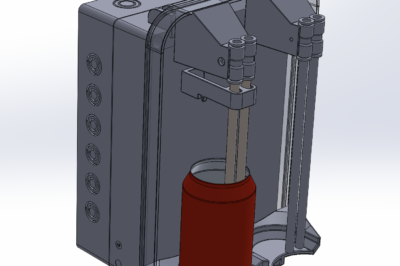

The LoniFiller (retired)

Inspired by the DuoFiller we designed our own dual can filler with automatic level sensors and purging. Please note that…

-

Foam booster

We do everything by the book and normally aim for about 2.4 volumes of CO2 i.e., use the pressure and…

-

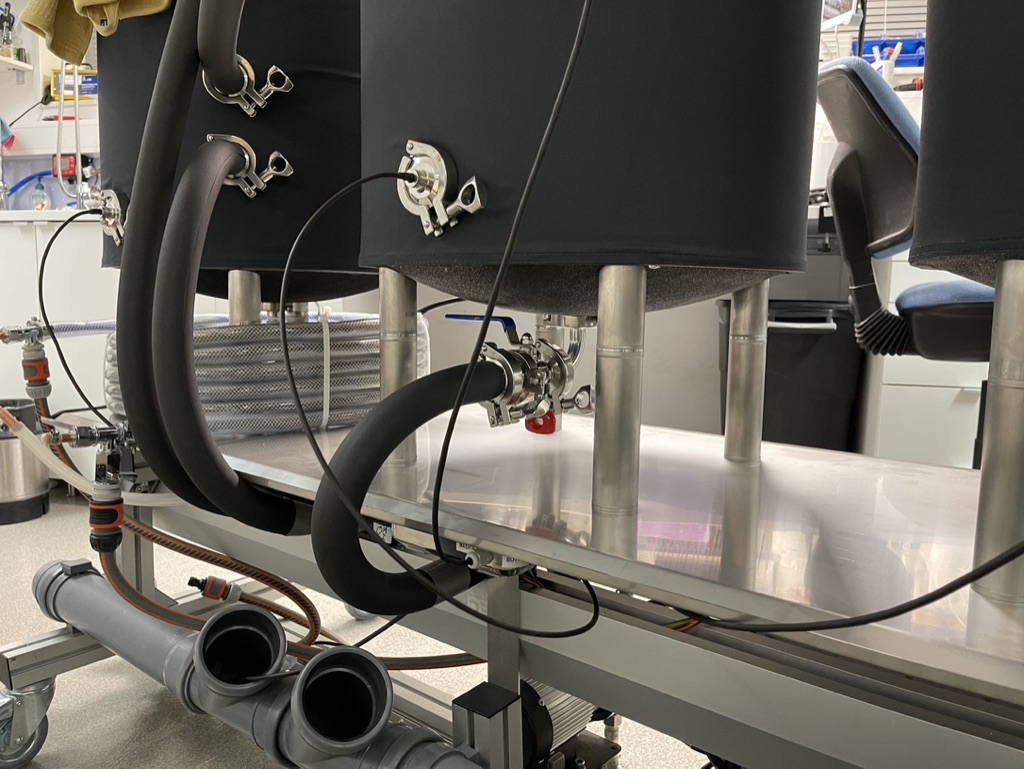

DIY glycol chiller and fermenter controller

When we invested in a Brewtools F80 fermenter we needed a glycol chiller for it. As usual we decided to…

-

Steam condenser

We do our brews in a garage, a large private garage but we do not want to destroy the ceiling…

-

Digital pressure sensor for the fermenter

Everything we do is connected 🙂 The pressure sensor of the fermenter is no exception. We used the same typ…

-

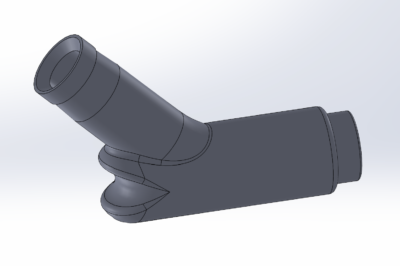

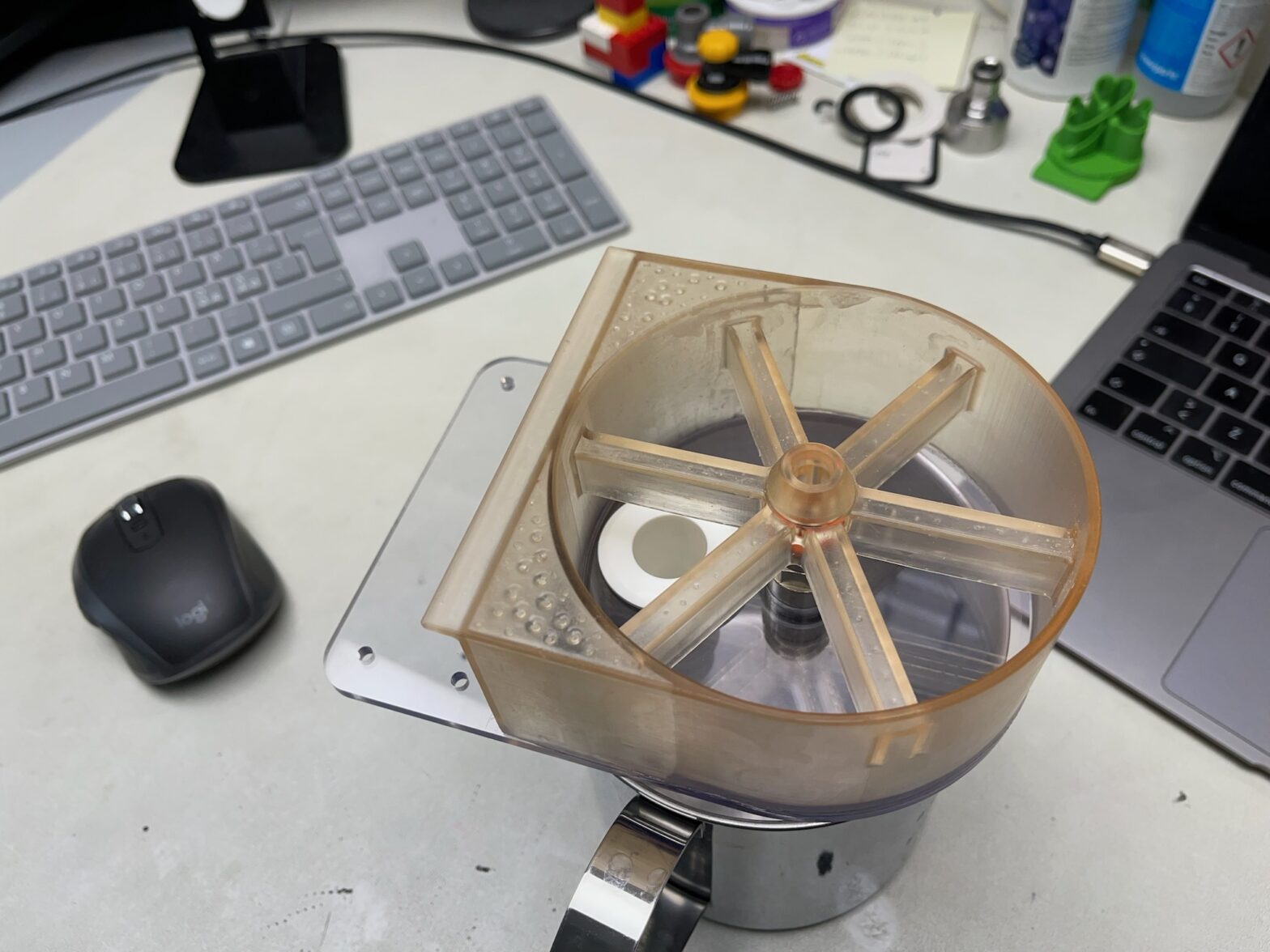

Sparge arm/mash manifold

We have used the “standard” sparge arm that is designed for the MLT but we wanted something that was more…

-

Digital “suction” sensor

Many brewers use manometers or clear hoses at the bottom of the MLT to monitor the pressure below the grain…

-

The servo valves (OLD)

These valves are now retired and replaced with Pneumatic pinch valves. About the only thing we salvaged from our first…

-

Temperature sensor system

We use six temperature sensors in the brewery for measuring the We use 1.5″ thermo wells for HLT, mash bottom…

-

DIY Counterflow Cooler (old)

At first we used a plate heat exchanger but they are a pain to clean and not very effective so…

-

Pyrex Erlenmeyer flasks

After preparing starters in a kettle and the transfer hot wort to no-name Erlenmeyer flasks and then cool them in…

-

The OLD mill (sold)

Well, its a mill with a power drill attached, mounted on a cutting board from IKEA. It is very sturdy…

-

Venturi pipe for flow measurements (OLD)

This system is now updated with a bigger version! We started with a traditional flow sensor with an impeller but…

-

Can rinser

To sanitize and wash out any dirt from the cans befor filling them we designed this little can rinser with…

-

Krausen buffer

After a few mishaps with krausen finding its way up the hose to our spunding valve (with our former fermenter),…

-

Magnetic stirrer for starters

Of course we need two magnetic stirrers for our nice Pyrex Erlenmeyer flasks to make starters in. And why buy…

-

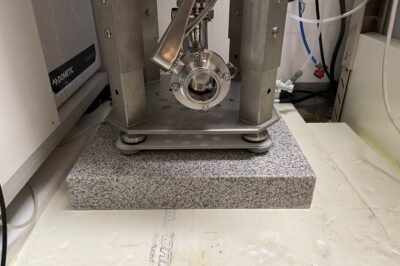

Orbital shaker for degassing SG samples

When we invested in an EasyDens SG meter we started to investigate the best way to degass samples for it…

-

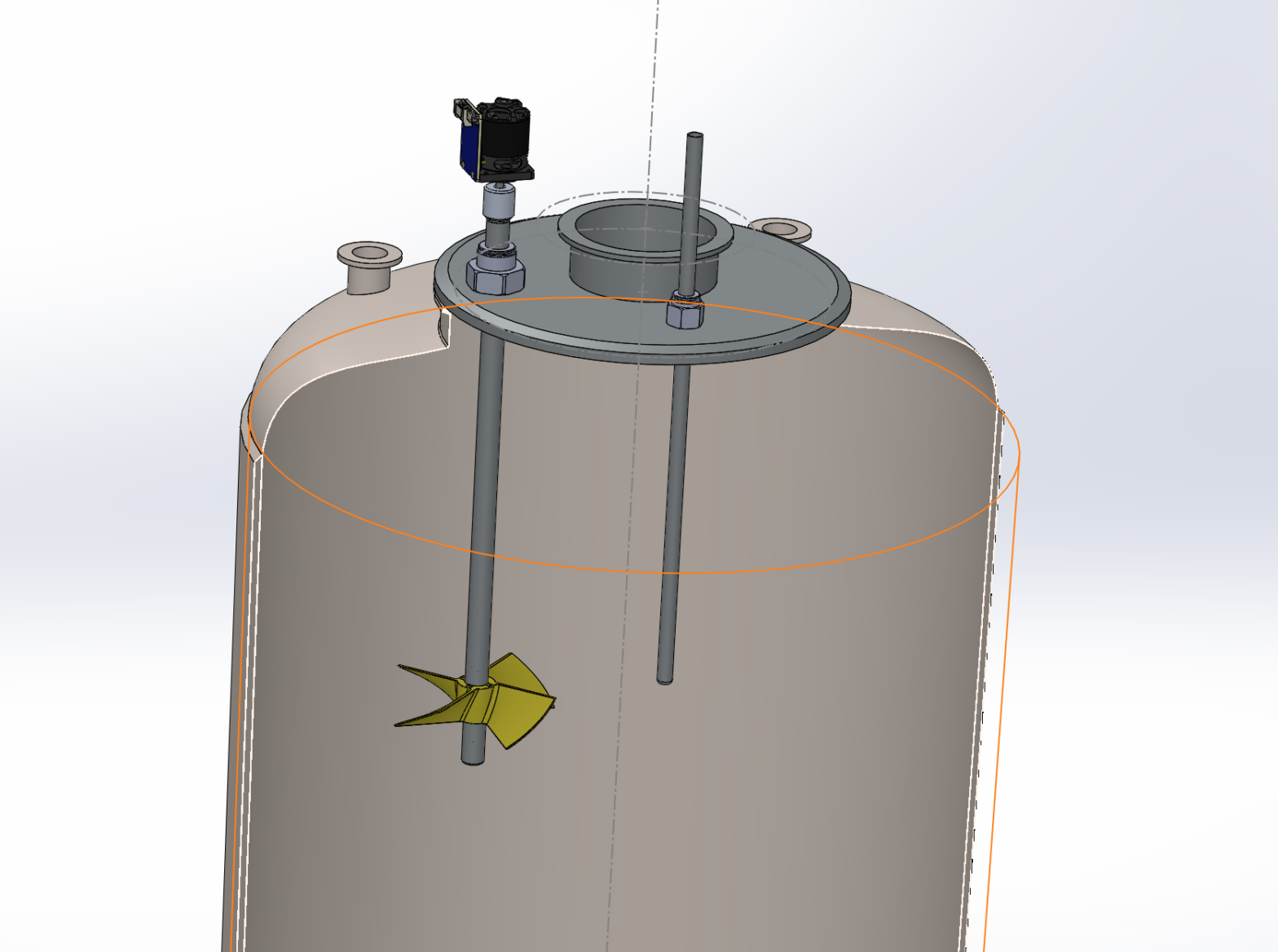

Suppressing temperature gradients in the fermenter

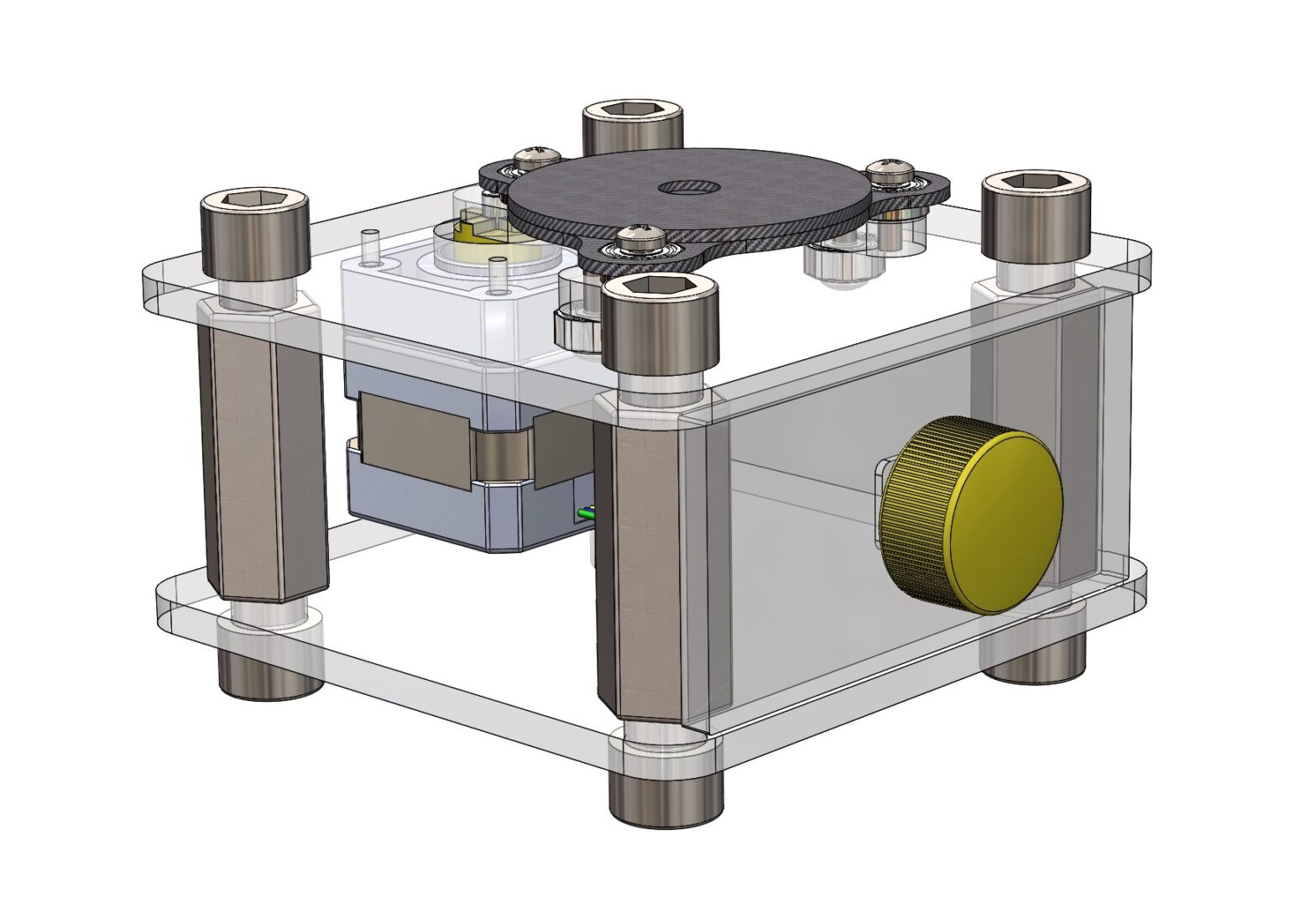

Due to the physical properties of liquids, especially water, there is a great gradient in temperature of the liquid in…