It all started with a Brewie B20 we bought through crowd founding 2015/2016(?). It took many years before we even fired it up and made our first beer in the autumn 2020. It did not take long before we started to modify it heavily and now there is not much left of the Brewie, actually the only thing left is a pump.

The system is heavily automated and anything that can be made in-house is, from software to hardware.

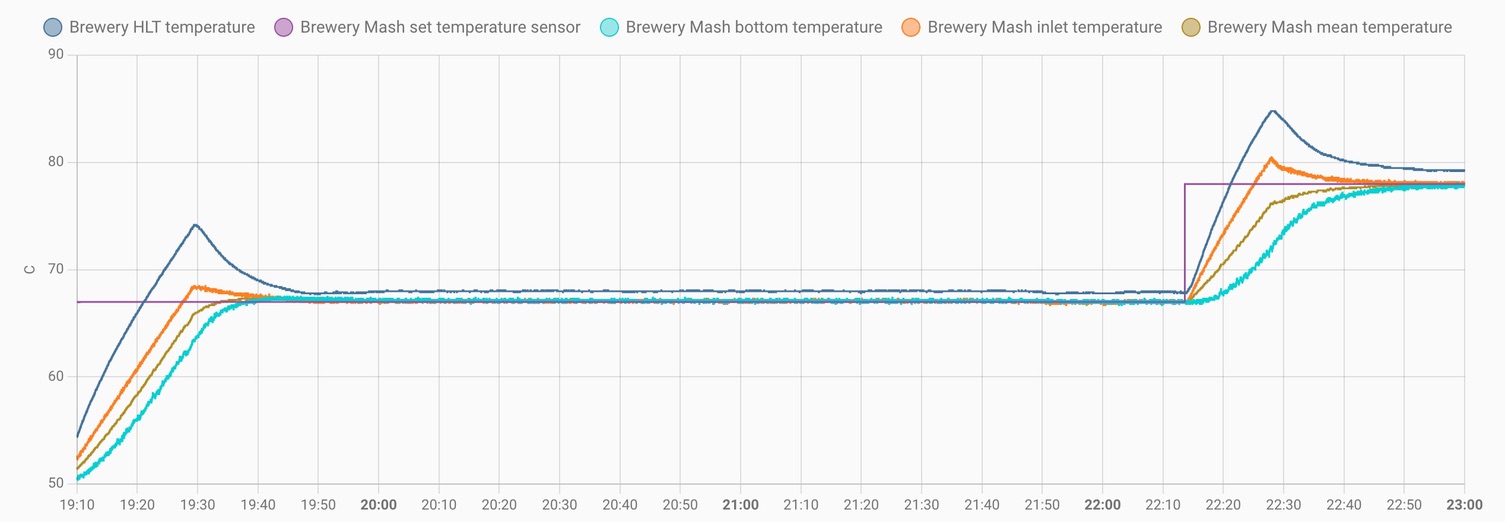

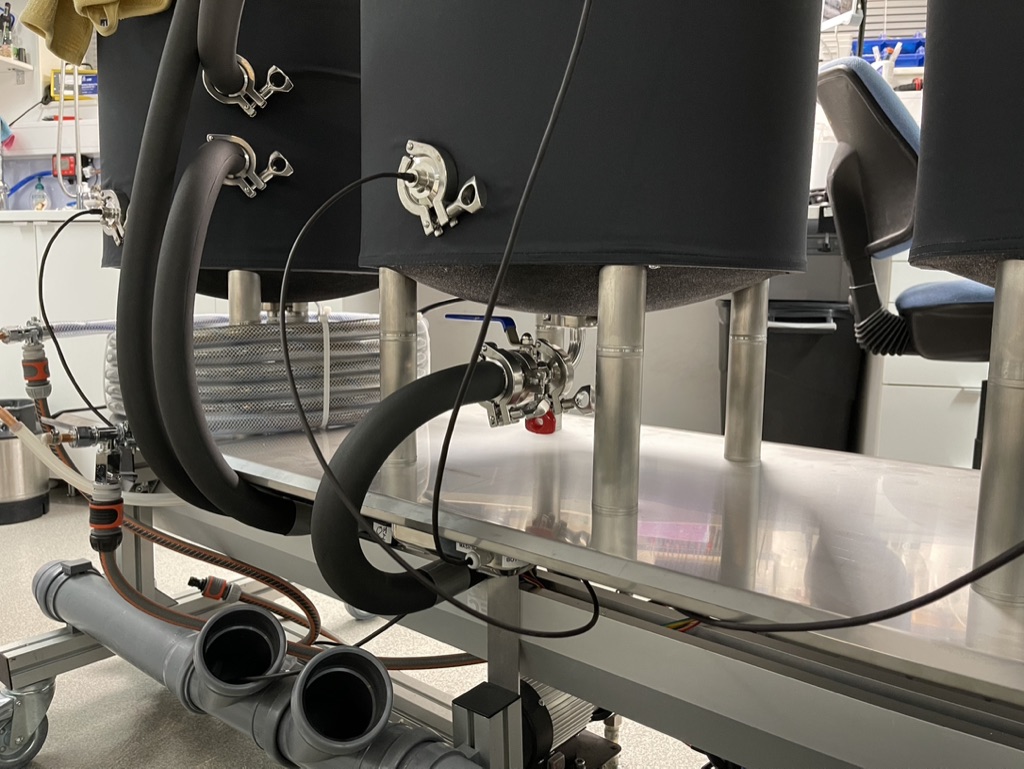

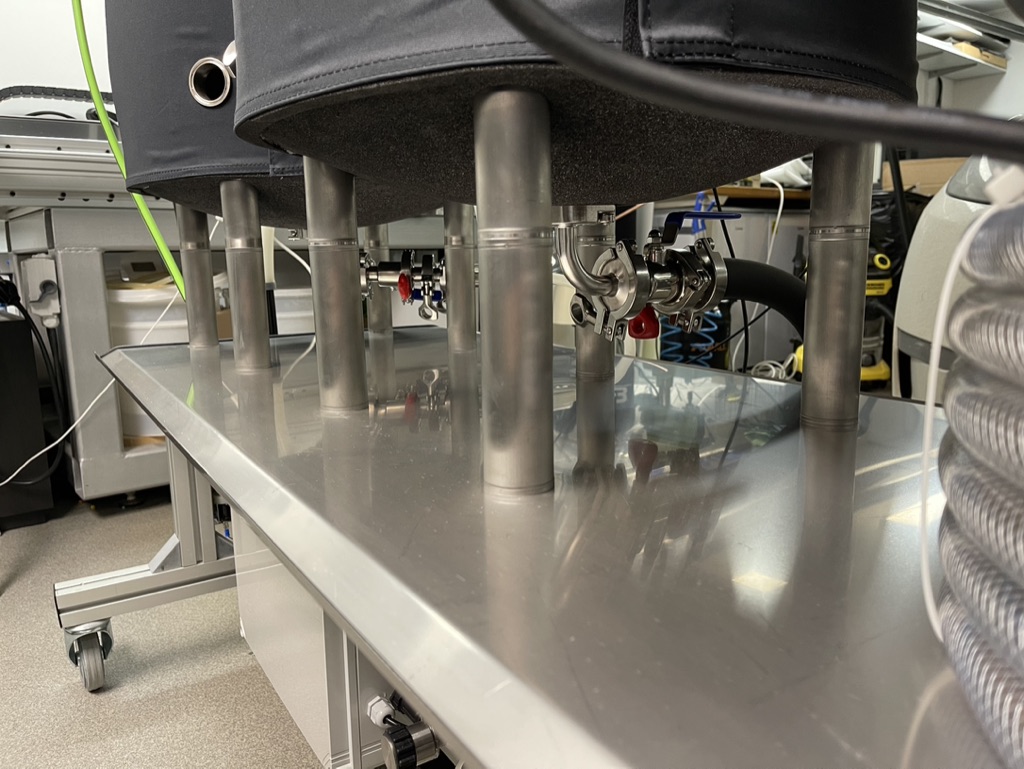

The system is in constant development so static images below is not always up to date.

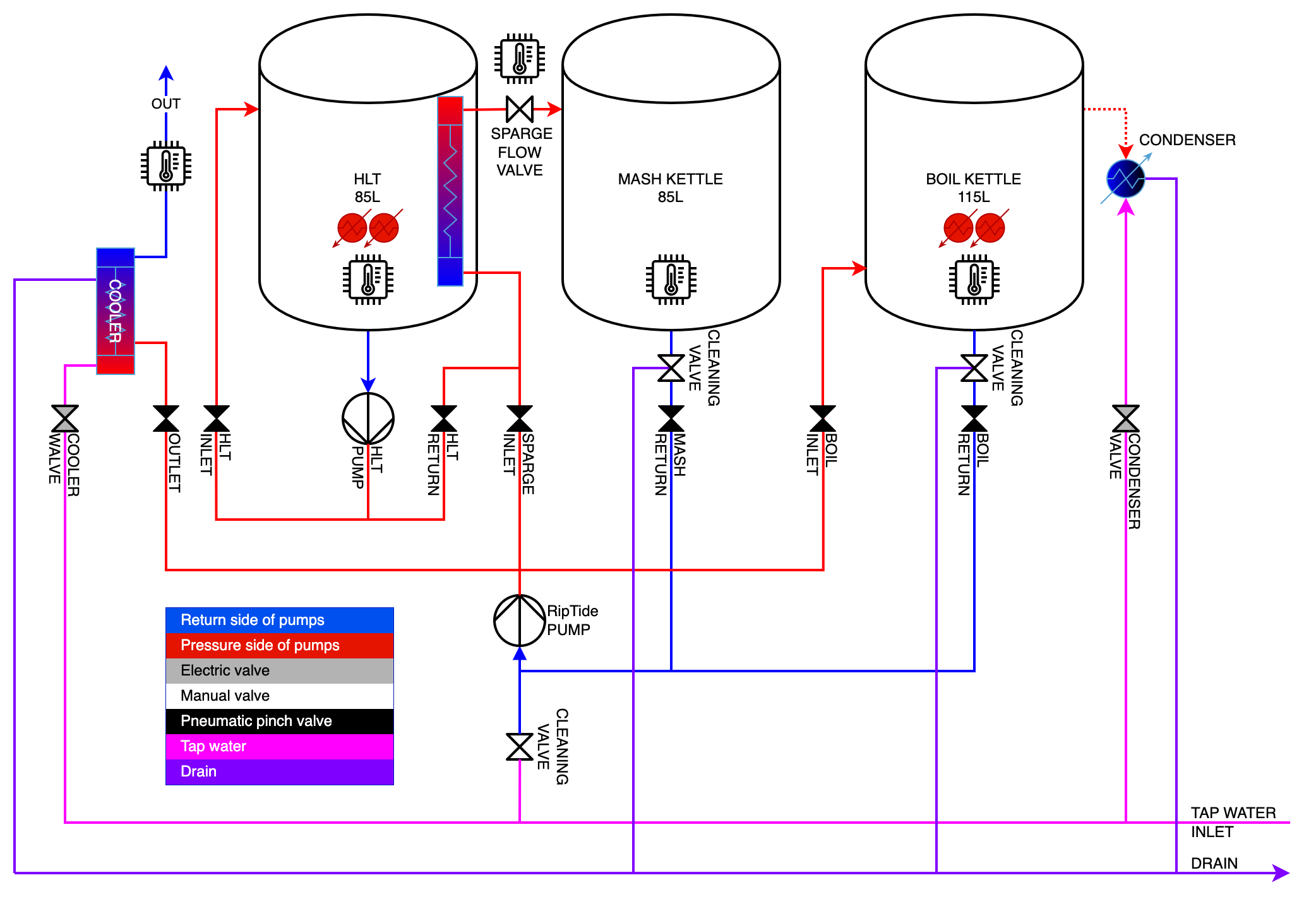

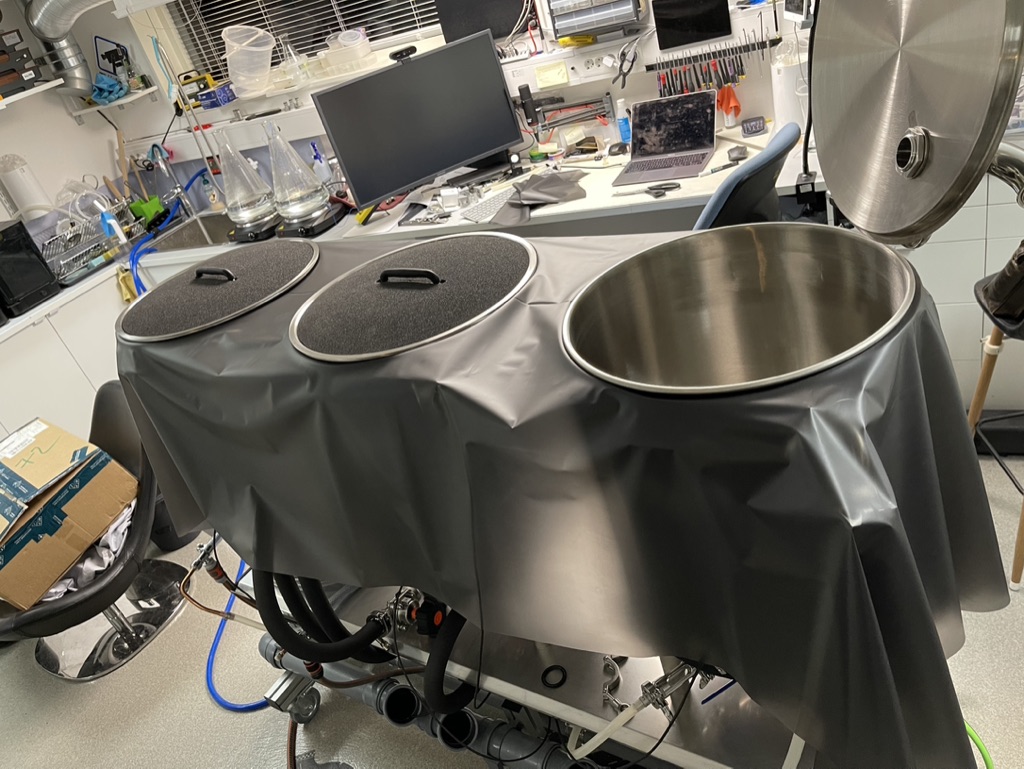

System overview

The system is a three kettle HERMS system capable of producing about 80L of wort.

Kettles and most of the stainless stuff is bought from Craft Hardware in Germany, we just love their great support and amazing quality products!

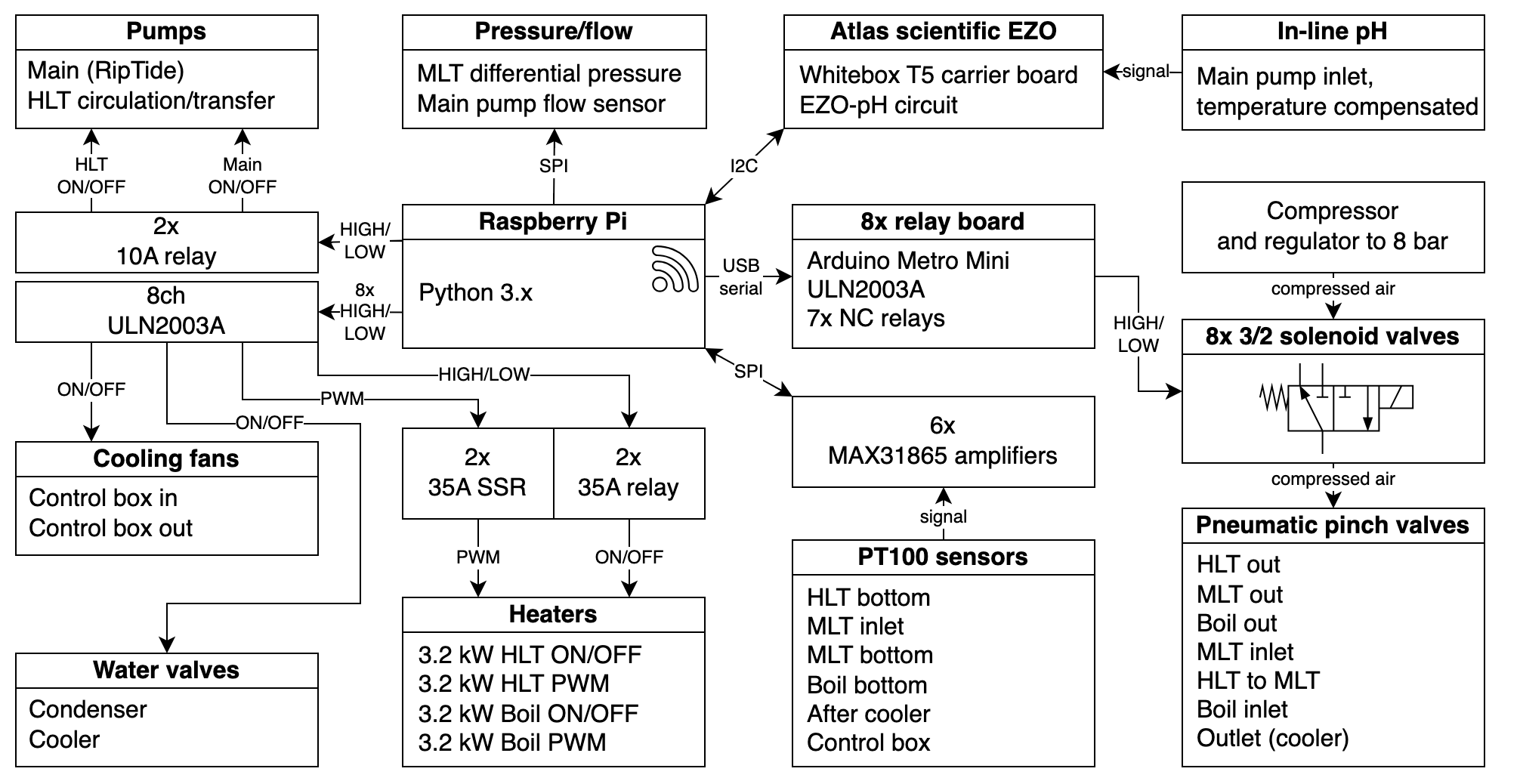

The Brain and software

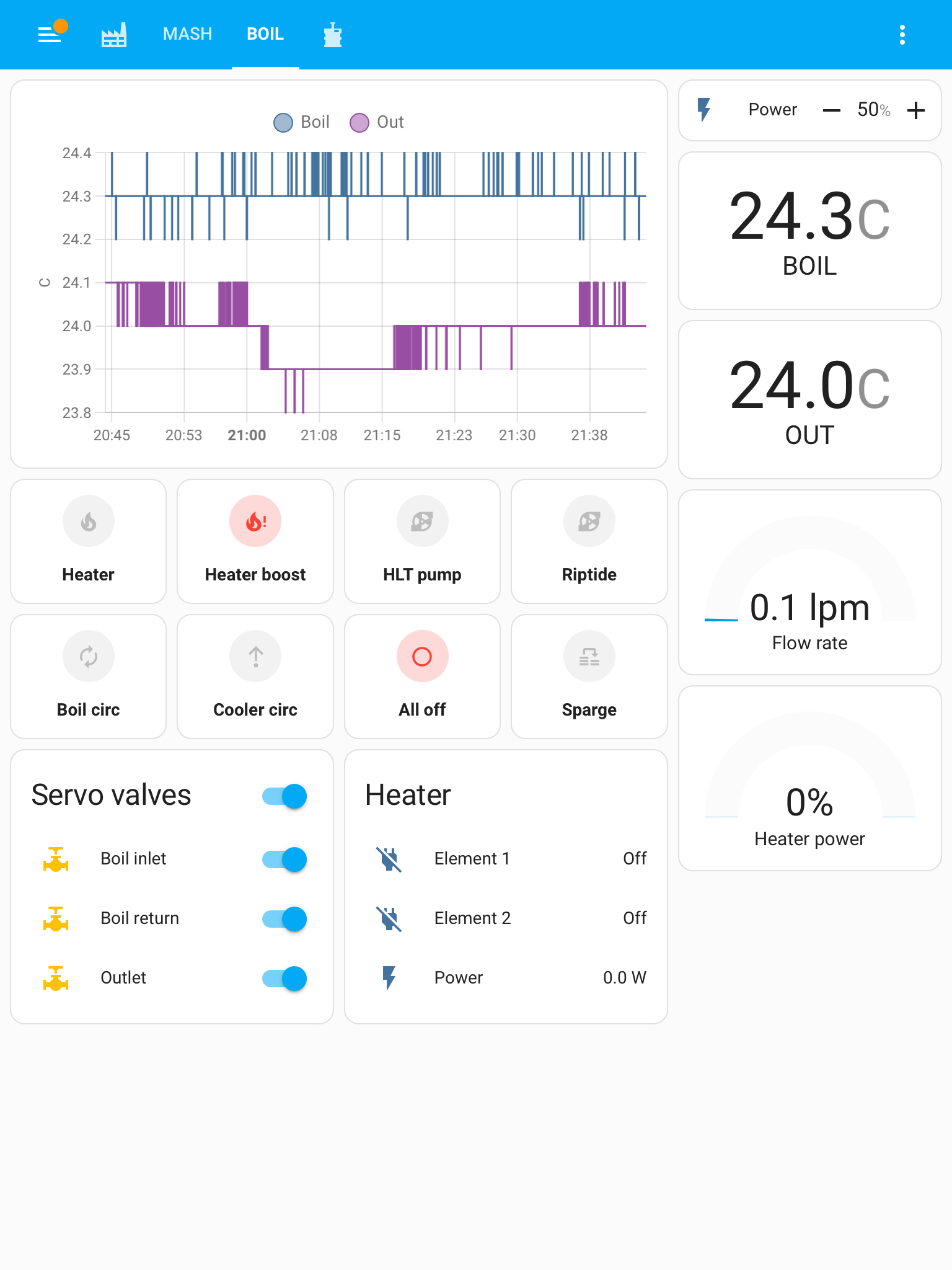

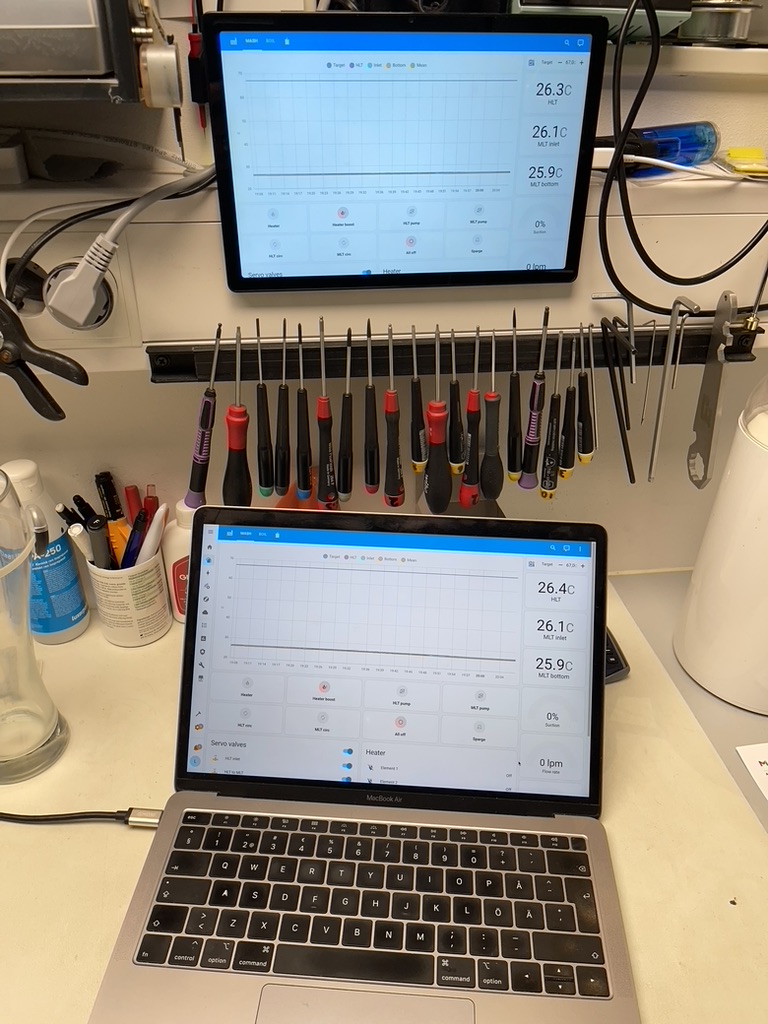

The firmware is python based and runs on a Raspberry pi together with a lot of peripherals, some of them linked further down.

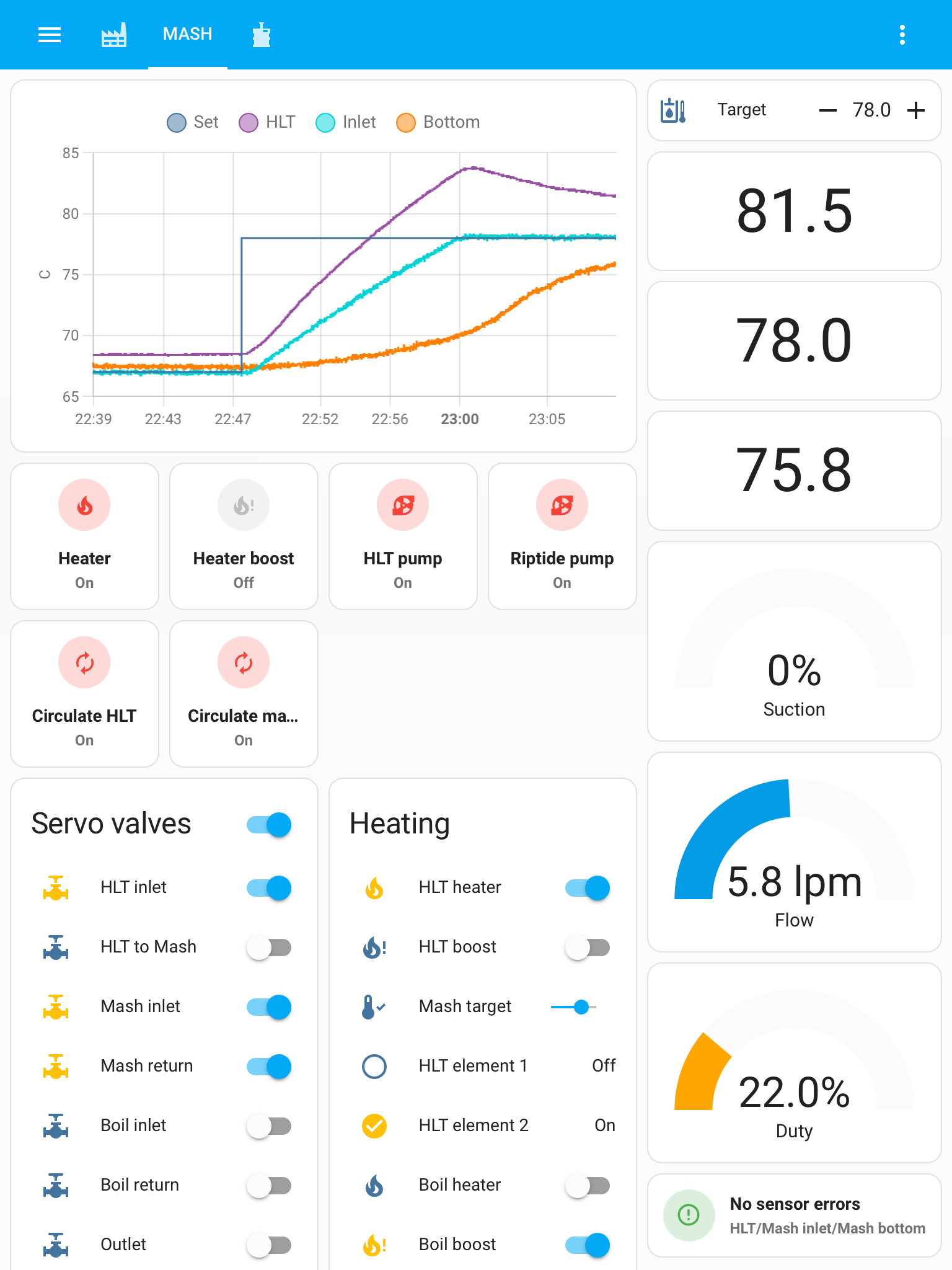

The firmware advertise itself as a MQTT device and is integrated in Home Assistant (HASS) where the GUI is built. The firmware is autonomous and can run all the important stuff like temperature control and safety features without HASS if network goes down. Literally all of the GPIOS of the RPi is occupied!

The firmware and GUI is under constant development and unfortunately we don’t have screenshots from a real brew, but maybe there will be.

Everything we’ve learned from developing this brewing system has been incorporated into our advanced LoniBrew™ controller, bringing professional-grade precision and automation to brewers of all scales.

More images of the system

More about different parts of the system

-

Sanitary pinch valves, updated design

Discover Our Redesigned Pinch Valves We’ve upgraded our original pneumatic pinch valves with a durable anodized aluminum body, offering enhanced…

-

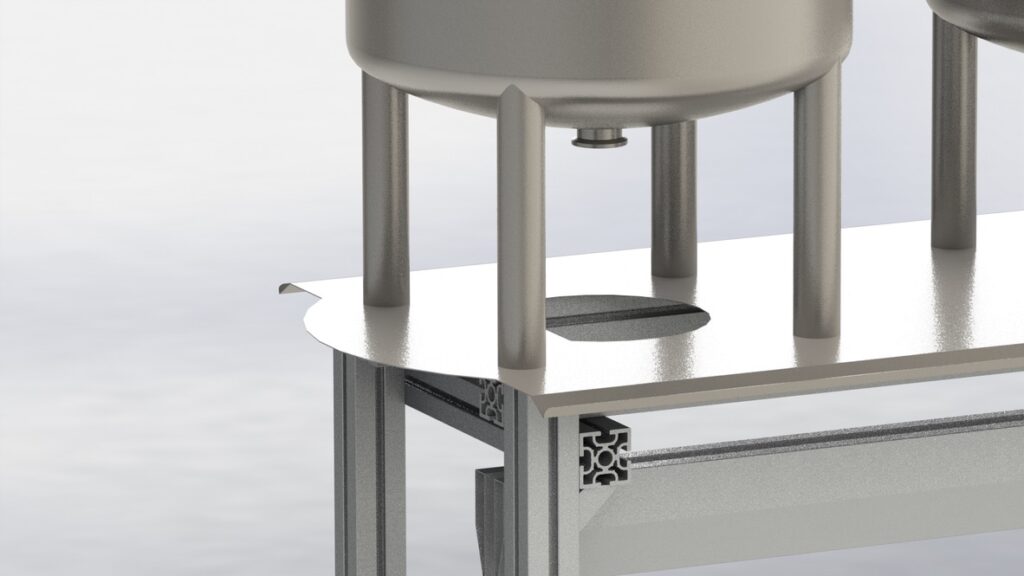

View our brewery in 3D

Not complete but you get the picture

-

Gammabrewery Showcases Innovative Brewing Solutions at Beer and Taste 2024

We’re excited to announce that Gammabrewery, in collaboration with Winterland Brewery and Lonitech AB, will be presenting our latest brewing…

-

The LoniBrew controller is here!

Read all about it at the systems main page!

-

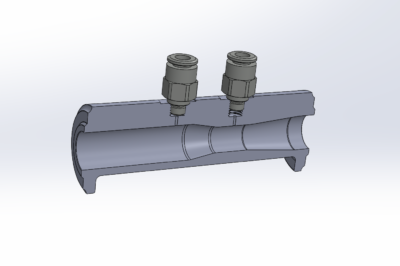

Venturi pipe for flow measurements

As we were going through the brewery’s hose system and replacing the sanitary valves, we also found the need to…

-

Pneumatic pinch valves

Due to our constant pursuit of enhancing our system, we began reevaluating hoses and flows within the brewing system. The…

-

CIP-lid for the brewery

We use a CIP-ball for the fermenter and it works really great. We would like to use CIP on our…

-

Steam condenser

We do our brews in a garage, a large private garage but we do not want to destroy the ceiling…

-

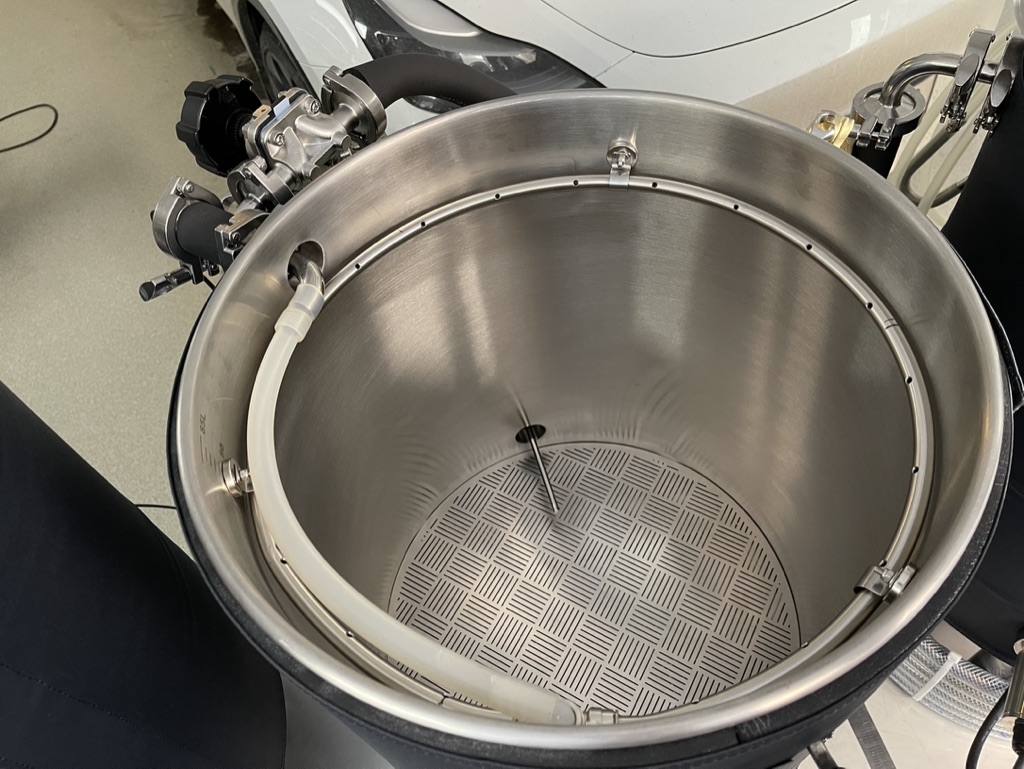

Sparge arm/mash manifold

We have used the “standard” sparge arm that is designed for the MLT but we wanted something that was more…

-

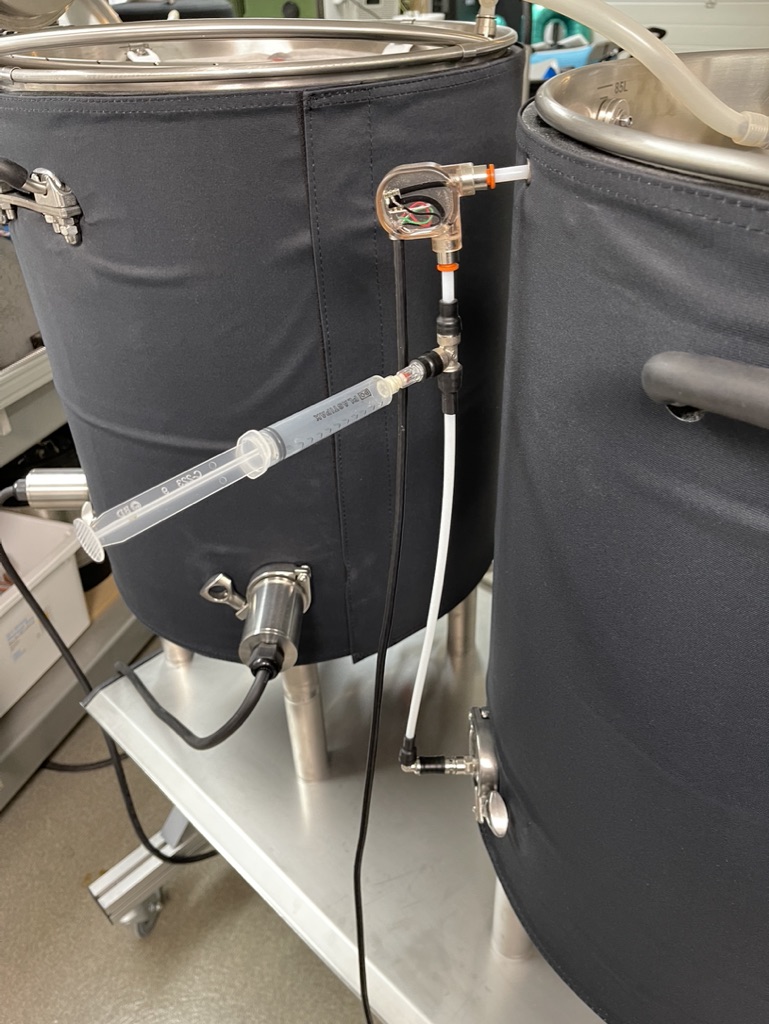

Digital “suction” sensor

Many brewers use manometers or clear hoses at the bottom of the MLT to monitor the pressure below the grain…

-

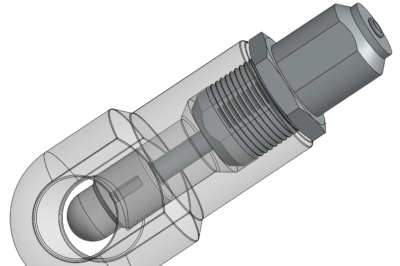

The servo valves (OLD)

These valves are now retired and replaced with Pneumatic pinch valves. About the only thing we salvaged from our first…

-

Temperature sensor system

We use six temperature sensors in the brewery for measuring the We use 1.5″ thermo wells for HLT, mash bottom…

-

DIY Counterflow Cooler (old)

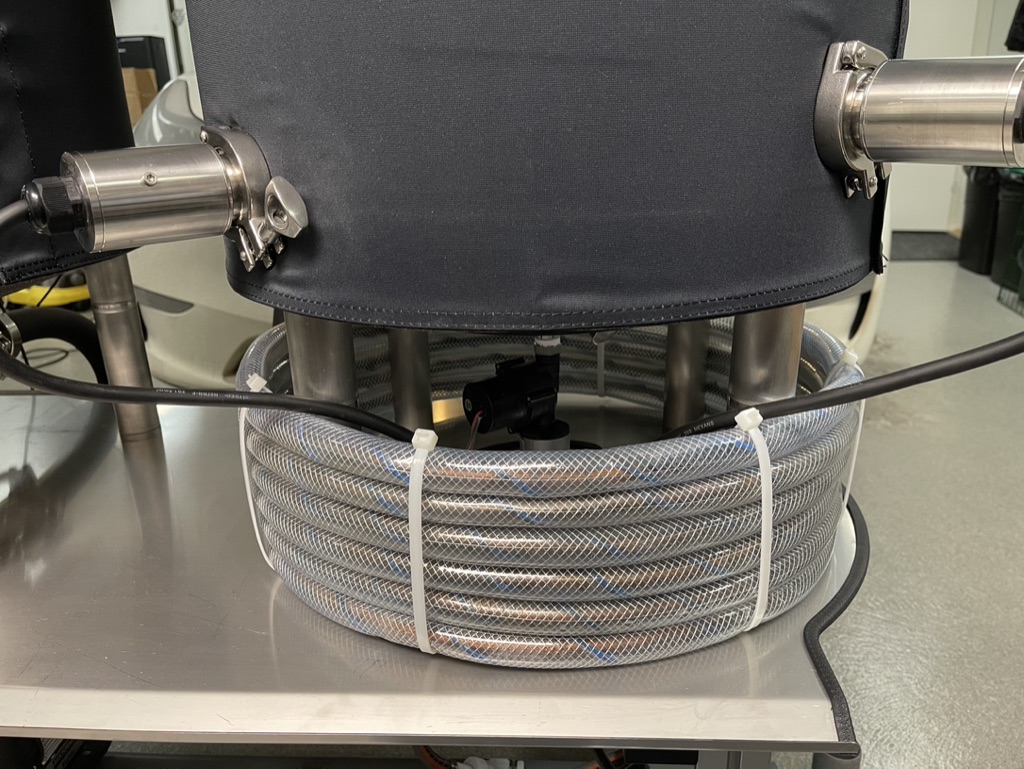

At first we used a plate heat exchanger but they are a pain to clean and not very effective so…

-

Venturi pipe for flow measurements (OLD)

This system is now updated with a bigger version! We started with a traditional flow sensor with an impeller but…