Brewery

-

Sanitary pinch valves, updated design

Discover Our Redesigned Pinch Valves We’ve upgraded our original pneumatic pinch valves with a durable anodized aluminum body, offering enhanced…

-

View our brewery in 3D

Not complete but you get the picture

-

Gammabrewery Showcases Innovative Brewing Solutions at Beer and Taste 2024

We’re excited to announce that Gammabrewery, in collaboration with Winterland Brewery and Lonitech AB, will be presenting our latest brewing…

-

The LoniBrew controller is here!

Read all about it at the systems main page!

-

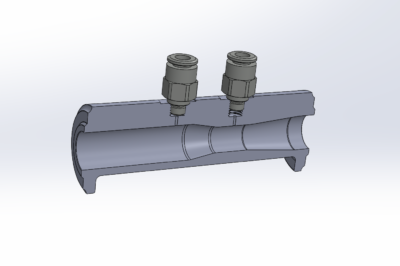

Venturi pipe for flow measurements

As we were going through the brewery’s hose system and replacing the sanitary valves, we also found the need to…

-

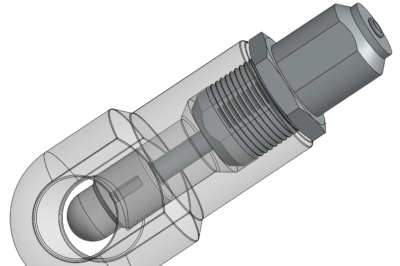

Pneumatic pinch valves

Due to our constant pursuit of enhancing our system, we began reevaluating hoses and flows within the brewing system. The…

-

CIP-lid for the brewery

We use a CIP-ball for the fermenter and it works really great. We would like to use CIP on our…

-

Steam condenser

We do our brews in a garage, a large private garage but we do not want to destroy the ceiling…

-

Sparge arm/mash manifold

We have used the “standard” sparge arm that is designed for the MLT but we wanted something that was more…

-

Digital “suction” sensor

Many brewers use manometers or clear hoses at the bottom of the MLT to monitor the pressure below the grain…

-

The servo valves (OLD)

These valves are now retired and replaced with Pneumatic pinch valves. About the only thing we salvaged from our first…

-

Temperature sensor system

We use six temperature sensors in the brewery for measuring the We use 1.5″ thermo wells for HLT, mash bottom…

-

DIY Counterflow Cooler (old)

At first we used a plate heat exchanger but they are a pain to clean and not very effective so…

-

Venturi pipe for flow measurements (OLD)

This system is now updated with a bigger version! We started with a traditional flow sensor with an impeller but…