Due to the physical properties of liquids, especially water, there is a great gradient in temperature of the liquid in a partially cooled vessel that is not agitated.

This can be seen if you drill a hole in the ice of a lake, you will (probably) find liquid water under the ice. Density of (liquid) water is the highest at about 4C and is therefor sinking to the bottom of the lake. Perfect for fishes, not so good when cold crashing beer 😉

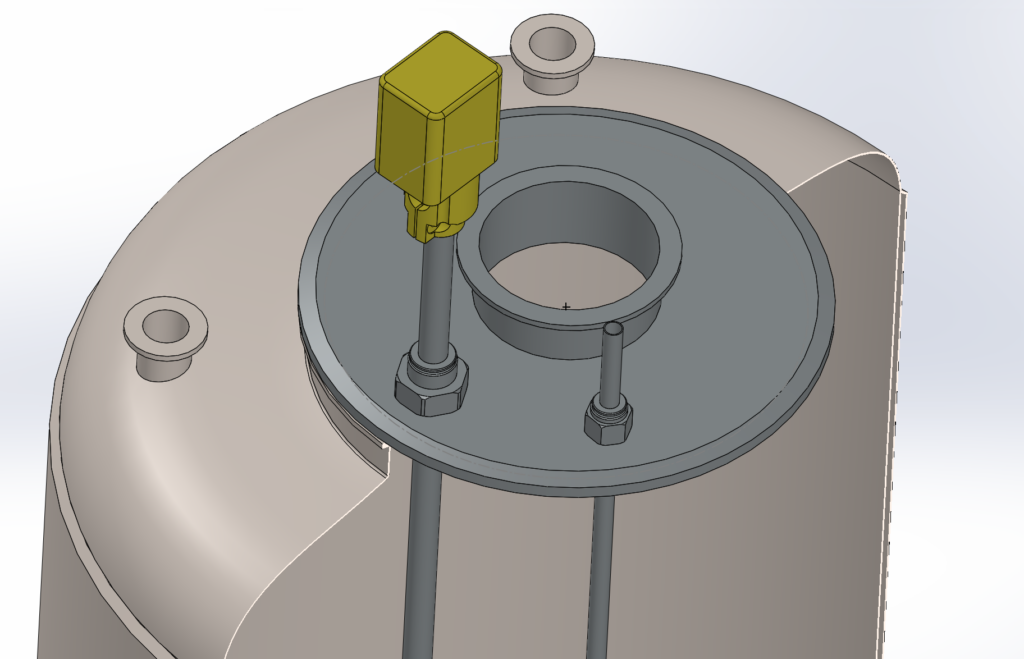

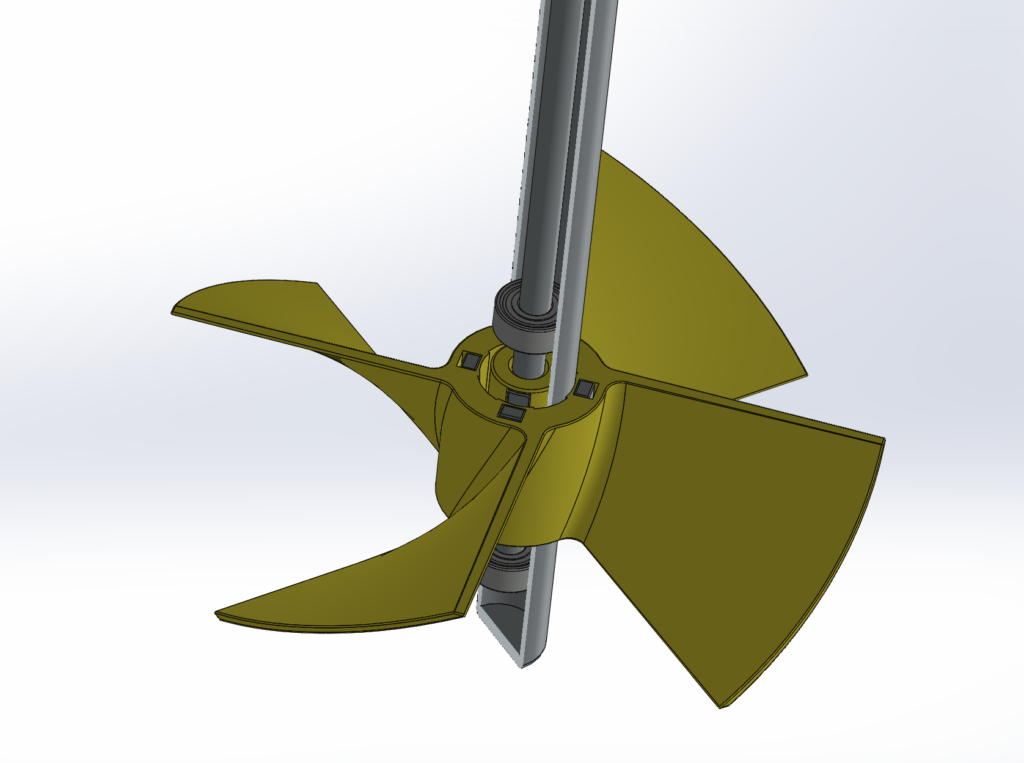

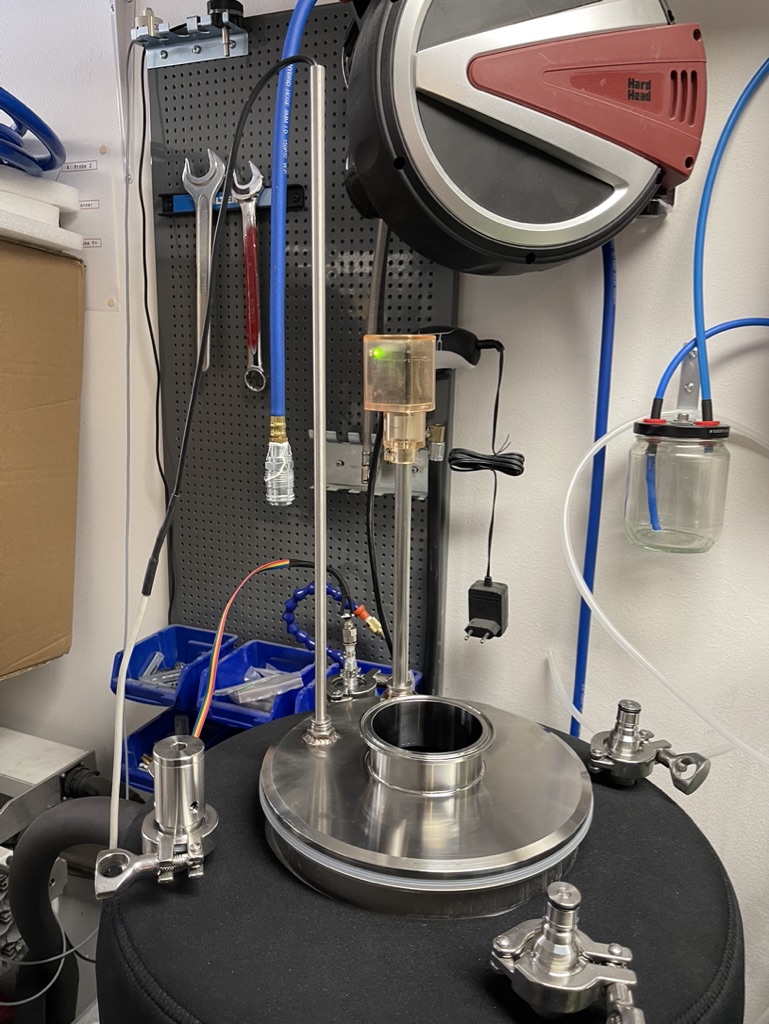

We have modified our Brewtools F80 Unitank to be able to measure the temperature at the top of the liquid as well as the original bottom position. We have also designed a highly controllable agitator that is integrated into the fermenter control system. The agitator transfers rotational momentum to a propeller via magnetism and the F80 is still capable of pressure fermentation. All parts in contact with the wort is made of stainless steel or printed in a biomedical FDA approved resin.

The agitator is based on a DC servo motor controlled over MODBUS RTU that can go from low to high RPM at “any” ramp, for the below results the RPM is set at 50 RPM when not actively cooling the fermenter and 150 RPM when cooling is active. The cooling system is a post of it’s own, it is not the usual on/off with a hysteresis system 😉

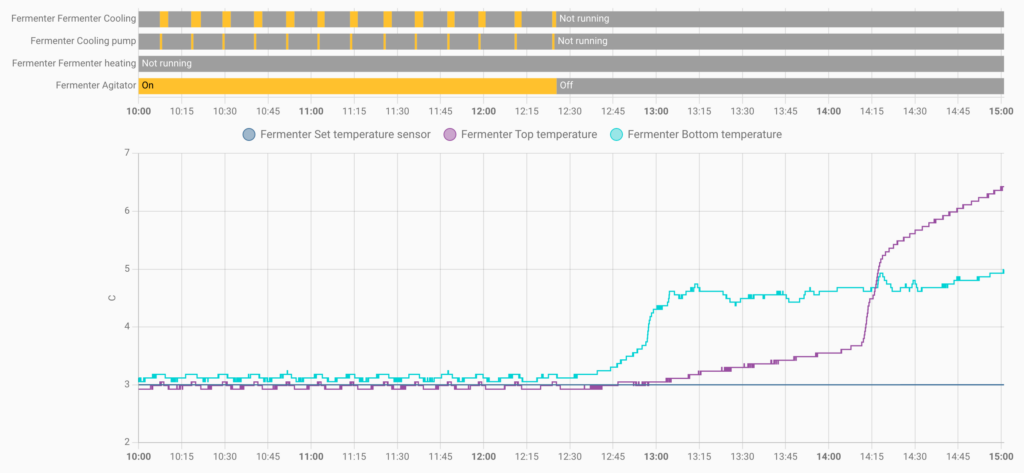

At the test above we are using 75L clean water and the cooling system is using the average temperature (top/bottom) for temperature regulation. As one can see the top and bottom temperatures start to diverge the moment we turn off the agitator. If one was to regulate on bottom sensor only and don’t measure the top temperature, all would look ok, but it wouldn’t be.

This is not a problem when the fermentation process creates agitation in the vessel by its own but right after pitch until the yeast starts to move things around and at the end of fermentation when the natural agitation is less vigorous, this is a real “problem”. Not to mention when doing a cold crash.

Below graph is a simulated scenario where the wort is about 22C when poured into the fermenter, then we would like to pitch at say 18C and starts to cool the fermenter. The bottom sensor is dropping quite fast but the top is not even moving. UNTIL we turn on the agitator 🙂

As soon as we turn off the agitator the top and bottom temperatures are diverging again. We can not simulate the phase when the fermentation is creating agitation with only water in the tank but we think that the natural agitation would be enough, until it is not enough 🙂

In the first graph we have also simulated a soft crash at 15C then a full cold crash down to 3C. Unfortunately we do not have data for our early tests without the agitator and only using the bottom sensor where we actually made ice slurry on the top before we reached below 4C at the bottom. The right/last graph below shows what happens if we turn off the cooler and agitator with the liquid at about 3C, the temperatures start to diverge and after a while they even cross each other, “yeah science, b*tch“

One of the main purposes of a cold crash is to let particles fall down to the bottom so it would probably be counterproductive to use the agitator when we reached target (i.e. 3C). TBD if a very slow agitation could be useful at this point.

We also think that the agitator could be useful for stirring up yeast if the fermentation has stalled, a quick swirl at higher RPM to really stirr stings up, TBD…

We’ll be back with the results from our next real brew!